Picture: STS 2030

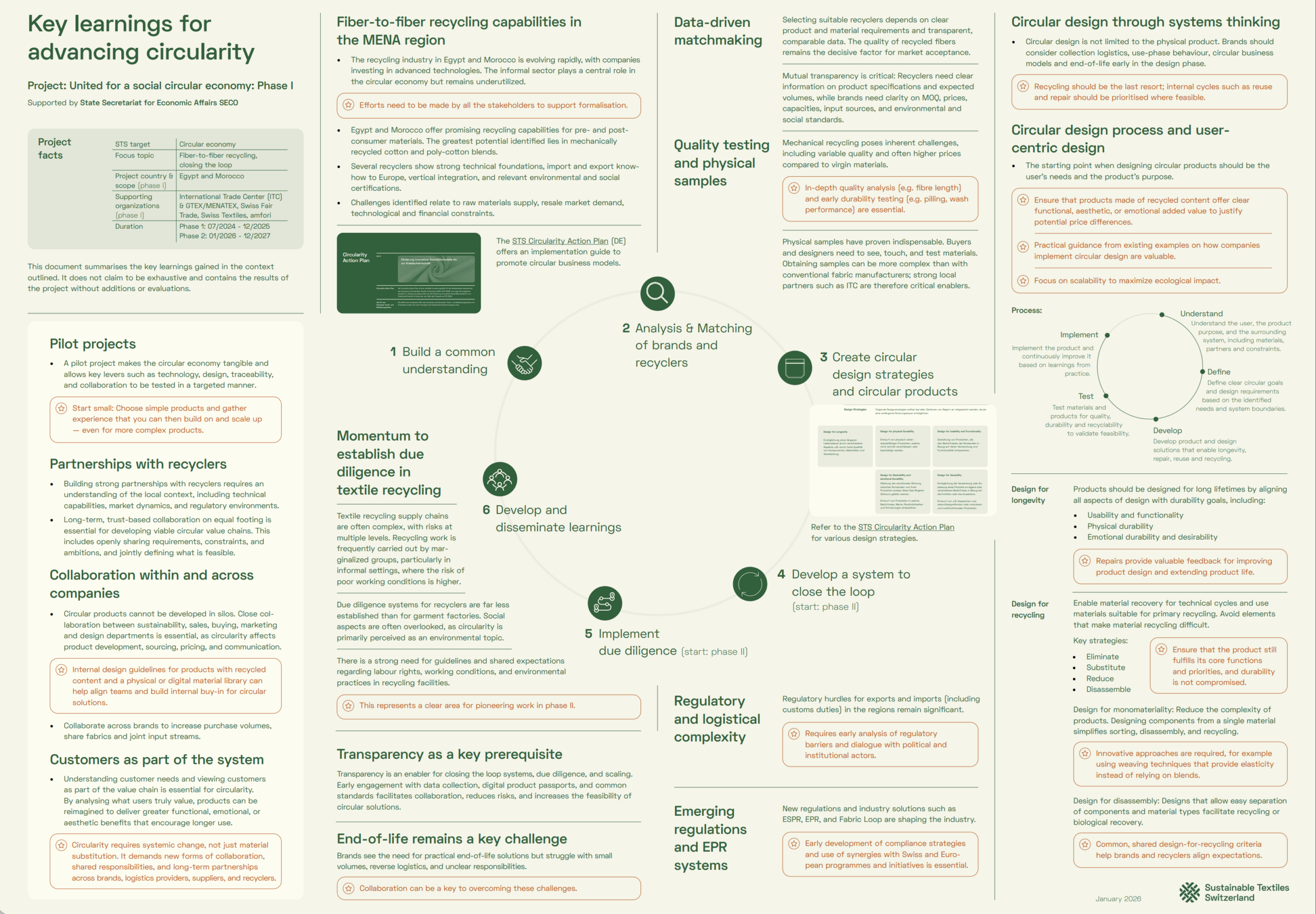

From fiber quality to reverse logistics: the pilot project “United for a social circular economy” reveals where circularity in the textile sector becomes concrete — and where it still falls short. Swiss brands and recyclers from the MENA region are jointly testing how textile loops can be closed. The learnings from Phase 1 show: collaboration and transparency are the key.

As part of the joint engagement “United for a social circular economy,” several companies and organisations collaborated in Phase 1 to advance fiber-to-fiber recycling and embed social aspects into circular value chains. The project focuses on the MENA region (Egypt and Morocco) and is funded by the State Secretariat for Economic Affairs (SECO). We are now sharing the key insights for the first time that can help all actors. Here is a short overview:

Recycling capacities in the MENA region are growing

The MENA region is rapidly developing: several recyclers demonstrate strong technical foundations, import and export know‑how with Europe, vertical integration, and relevant environmental and social certifications. Challenges remain in raw material supply, market demand, and technological and financial constraints. The informal sector plays a central role but is still insufficiently integrated and poses risks to working conditions and the environment.

Data-driven matchmaking and quality assessment

The selection of suitable recyclers depends on clear product and material specifications as well as transparent, comparable data. The quality of recycled fibers remains the decisive factor for market acceptance. Detailed quality analyses (e.g., fiber length) and physical samples are indispensable: buyers and designers must be able to touch, test, and compare the material with conventional fabrics.

Circular design requires systemic thinking

Circular products cannot be developed in isolation. Close collaboration between sales, sourcing, design and product development is essential. The starting point should be the user perspective. To achieve long service lives, products made from recycled material must offer functional, aesthetic or emotional added value. Recycling should be the final stage at the end of a long product life – inner loops such as reuse and repair take priority.

Due Diligence and social aspects

Textile recycling supply chains are often complex, with risks at multiple levels. Recycling is frequently perceived as an environmental issue — social aspects are often overlooked. Marginalized groups often work in recycling facilities, particularly in the informal sector, where the risk of poor working conditions is higher. There is a strong need for shared guidelines and expectations on labor rights, working conditions and environmental practices in recycling facilities.

Transparency provides the foundation – end-of-life remains the hurdle

Digital product passports, traceability and common standards only make collaboration between brands and recyclers possible in the first place. But what happens to the product after its use remains the biggest challenge: low return volumes, missing take‑back logistics and unclear responsibilities slow the loop. Brands that collaborate – for example through joint collection and return schemes – can overcome this hurdle.

The upcoming second phase focuses on concrete implementation: together with recycling partners in Morocco and Egypt, the first market-ready products made from recycled fibers will be created, while the entire circular process chain is practically tested.